Composite materials for wind turbine blades pdf

Composites for stronger and lighter wind turbines Wind turbine designs continually improve the turbine’s power output capacity and performance. Blade design is critical, and as turbine manufacturers look to design and manufacture longer, stronger, and lighter blades , composite technologies play a critical role.

Kirk attributes materials and manufacturing for letting turbine blades keep up with ever-growing towers. “Because of composite materials, blades can spin faster and capture winds at lower velocity. Composites offer wind manufacturers strength and flexibility in processing with the added benefit of a lightweight material,” he says.

New materials for wind turbine blades such as carbon, carbon-hybrid, S-glass and new material forms 5. Design details to minimize stress concentrations in ply drop regions 6. Less expensive, embedded blade attachment devices. III.MATERIALS FOR WIND TURBINE BLADES The material selection of the wind turbine blades plays an important role in the wind turbine designs. In selecting materials …

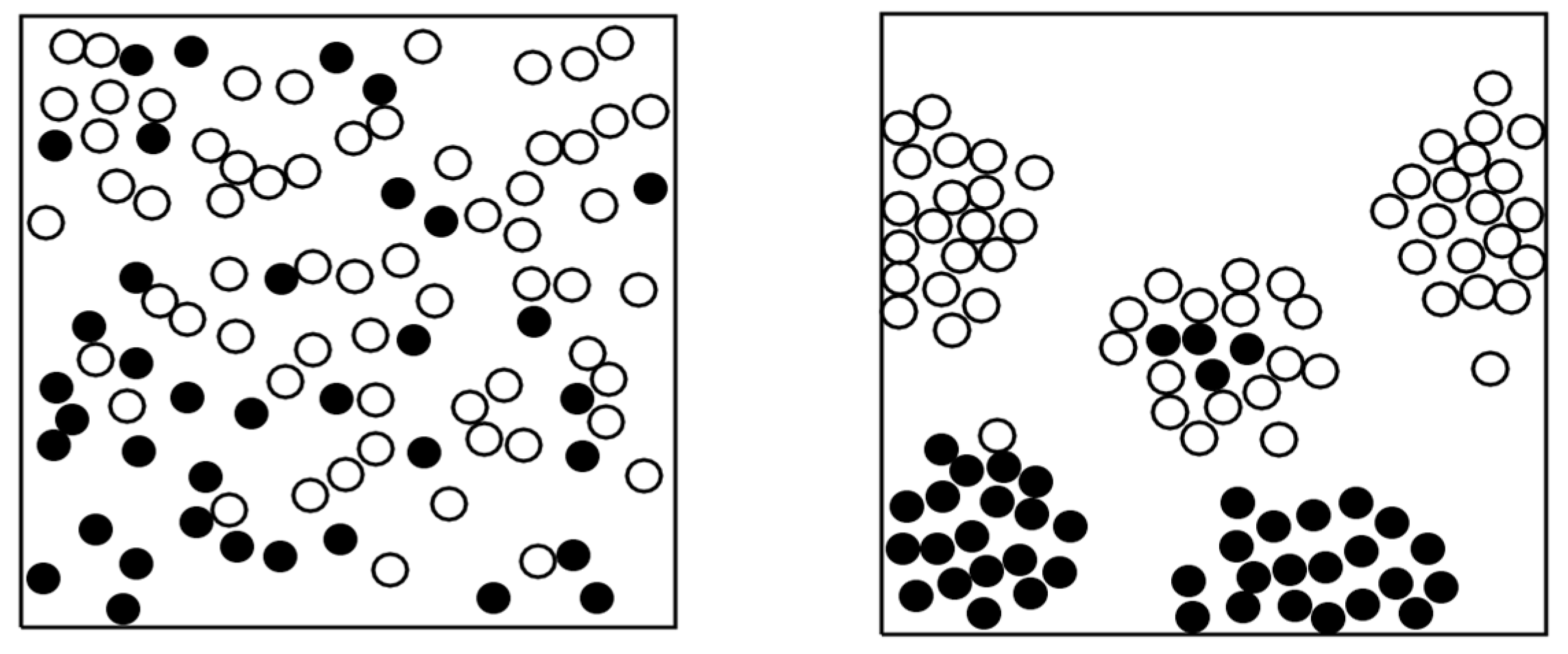

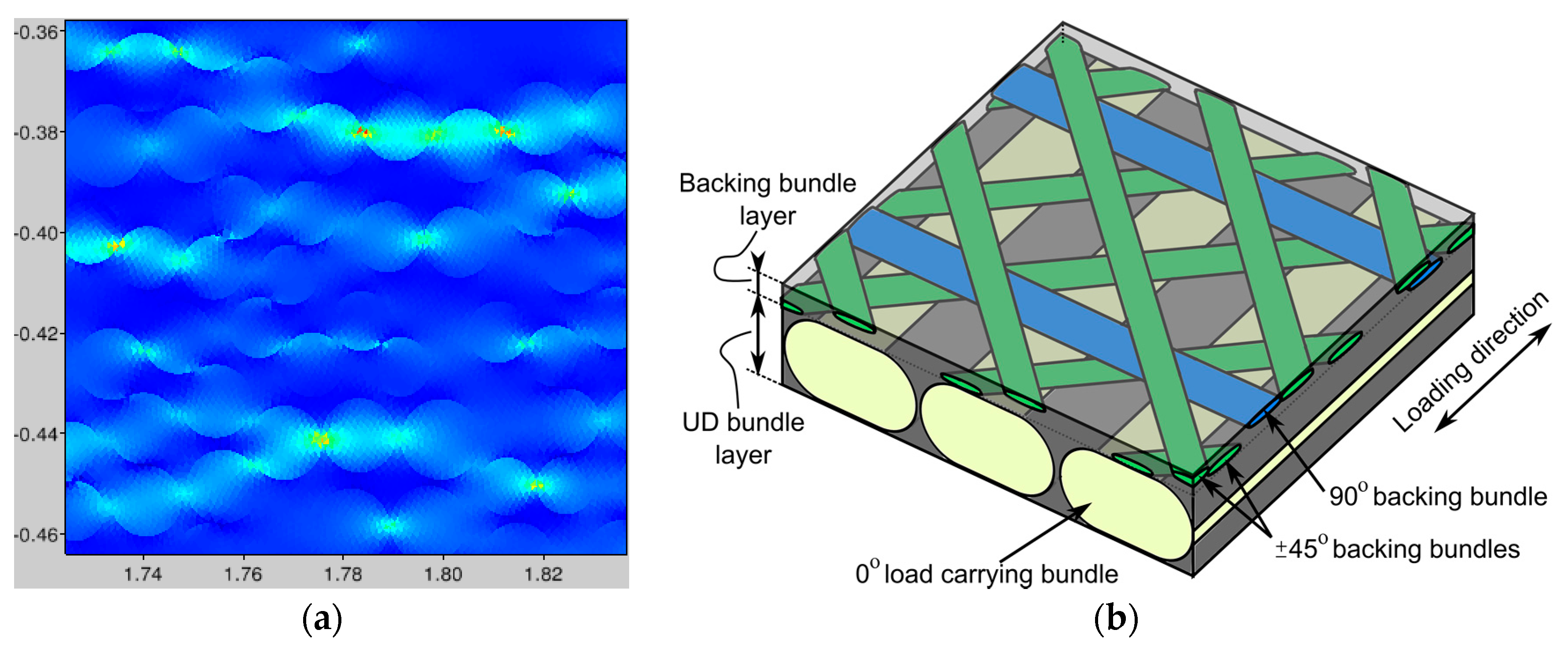

Currently, most widely-used composites for wind turbine blades are glass fiber/epoxy composites, while investigations using carbon, aramid and basalt fibers, thermoplastics polymers, and bio-based and nanoengineered materials are under way, and also have the potential of …

Alternative Composite Materials for Megawatt-Scale Wind Turbine Blades: Design Considerations and Recommended Testing . Journal of Solar Energy Engineering , 125 , …

Materials for Wind Turbine Blades. Material Science and Renewable Energy: Wind Energy The British University in Egypt, El-Shorouk City March 25, 2015 7 MW – 83.5 m blade Off-shore wind turbine SSP, Denmark (2013) Material Science and Renewable Energy: Wind Energy The British University in Egypt, El-Shorouk City March 25, 2015 y = 0.0005×2.6589 0 5 10 15 20 25 30 0 10 20 30 40 50 60 70 Blade

recycling Article Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing Lawrence C. Bank 1,*, Franco R. Arias 1, Ardavan Yazdanbakhsh 1, T. Russell Gentry 2,

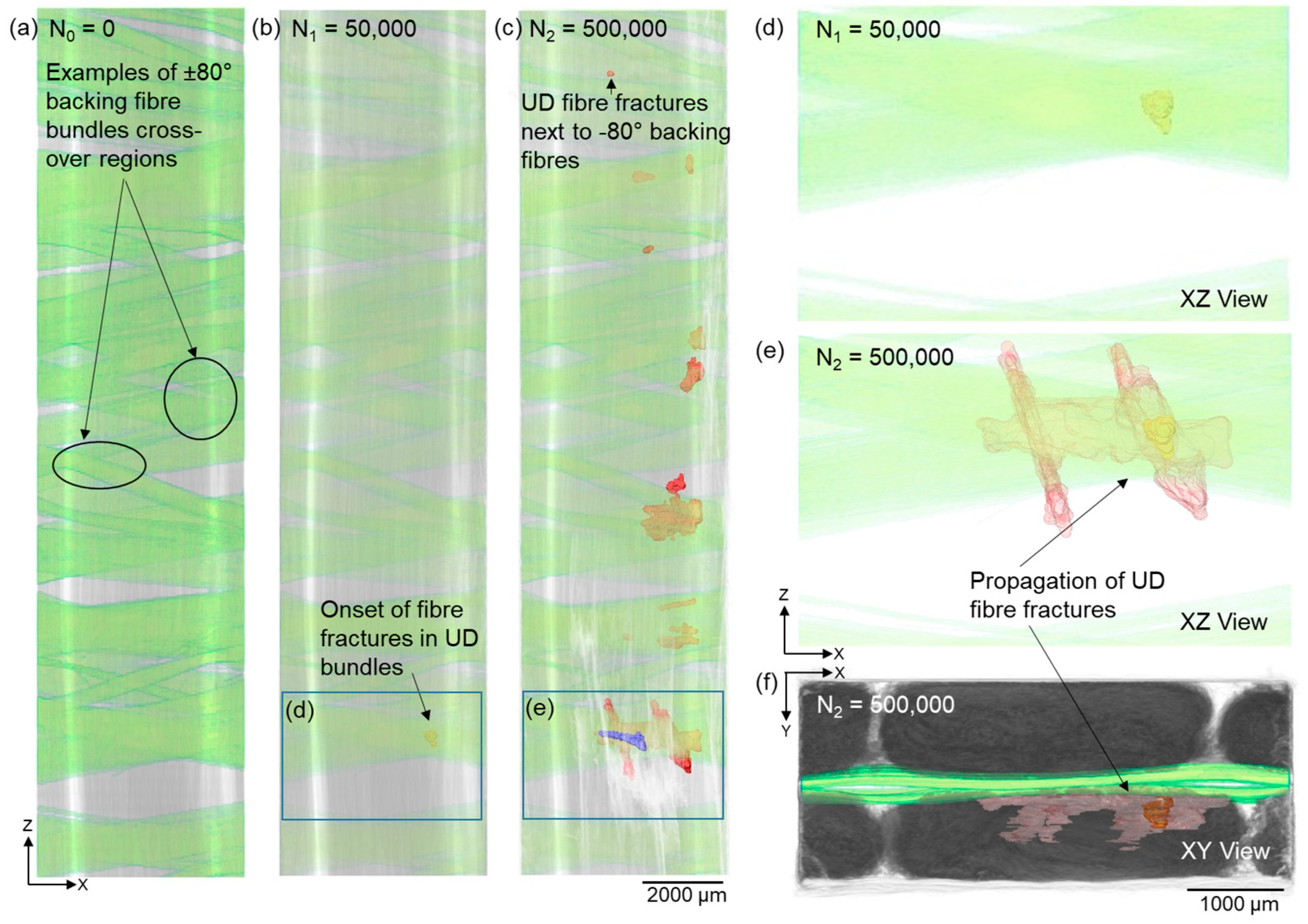

An overview is given of the use of composite materials in wind turbine blades, including common failure modes, strength-controlling material properties, test methods and modelling approaches at the materials scale, sub-component and component scale.

General Assessment of Fiber-Reinforced Composites

Analysis on Wind Turbine Blade Using Composite Materials

Wind turbine blades Department of Mechanical, Chemical and Materials Engineering University of Cagliari, Italy 2 Wind turbine blades are complex structures whose design involves the

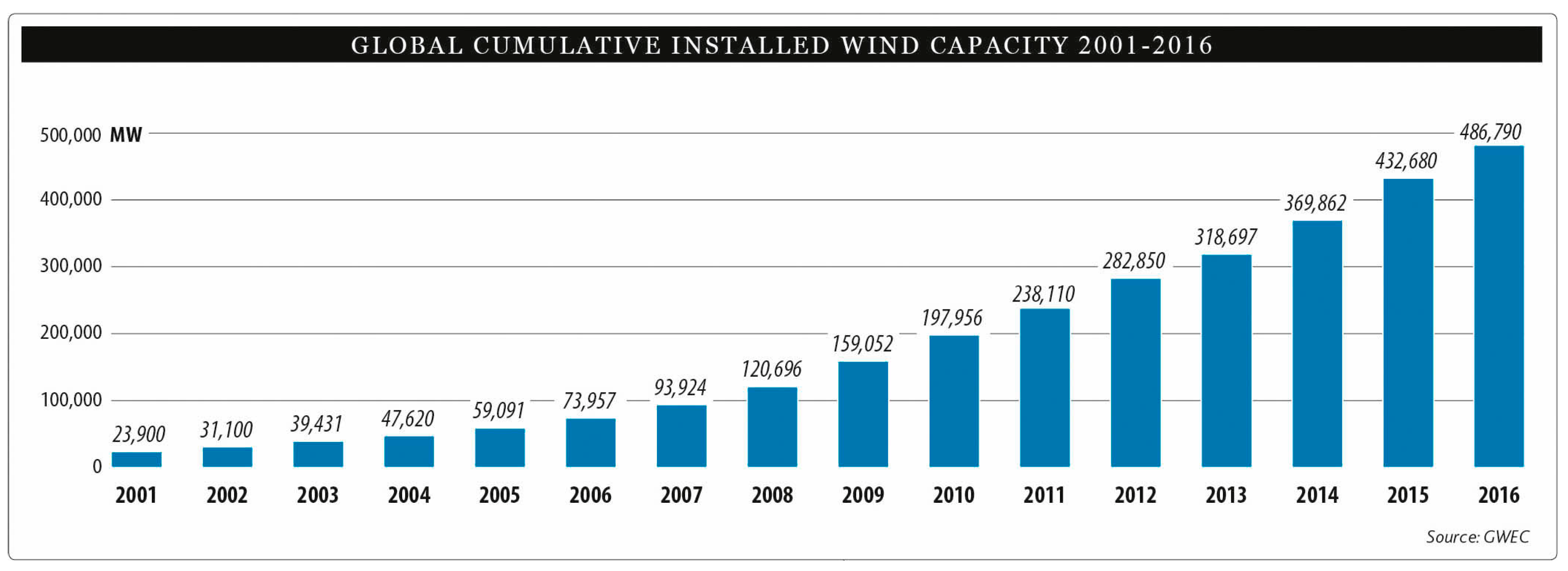

Wind Turbine Composites Material Market worth 12.17 Billion USD by 2021 DOWNLOAD PDF ; Blades: Largest application segment of the wind turbine composite market. The blades segment is the largest application segment of the wind turbine composite market. Blades account for the highest amount of composite consumption in their manufacturing. The use of composites in wind turbine blades

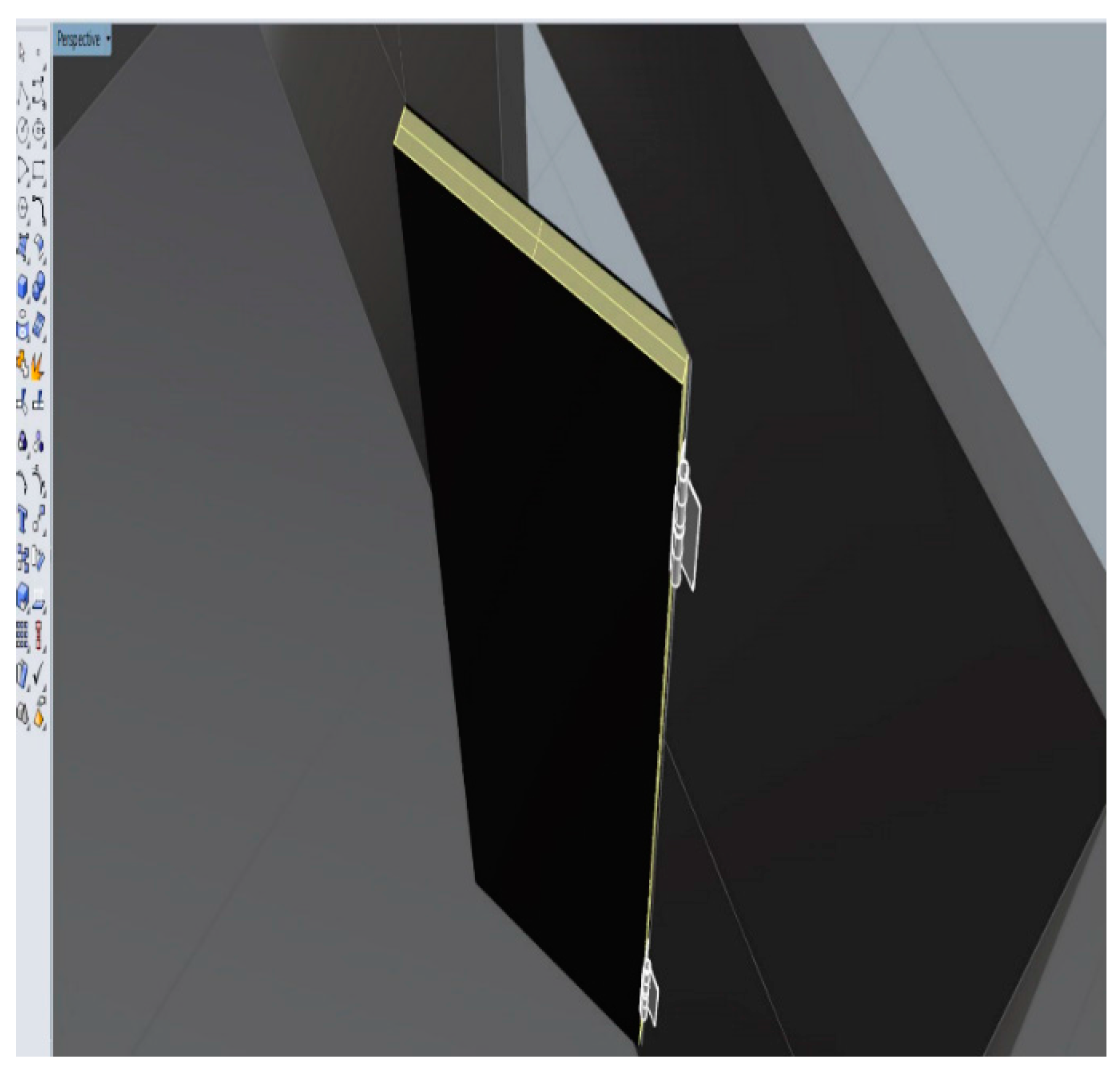

In the drawings, FIG. 1 shows a wind turbine blade 10 while FIG. 2 shows a wind turbine blade of the spar-shell type in the process of fabrication. As shown, the blade 10 is formed by helically winding a filament-reinforced tape 12 about a form 14 to fashion a shell 16 in a single pass. For the purposes of this invention, the term tape means a generally elongated continuous material having a

The efficiency of the wind turbine depends on the material of the blade, shape of the blade and angle of the blade. Therefore, the material of the turbine blade plays a vital role in the wind turbines.

SmartManufacturingSeries.com Additive Manufacturing of Wind Turbine Blades Using Thermoplastic Composite Material

– 148 – Recent Advances in Composite Materials for Wind Turbine Blades

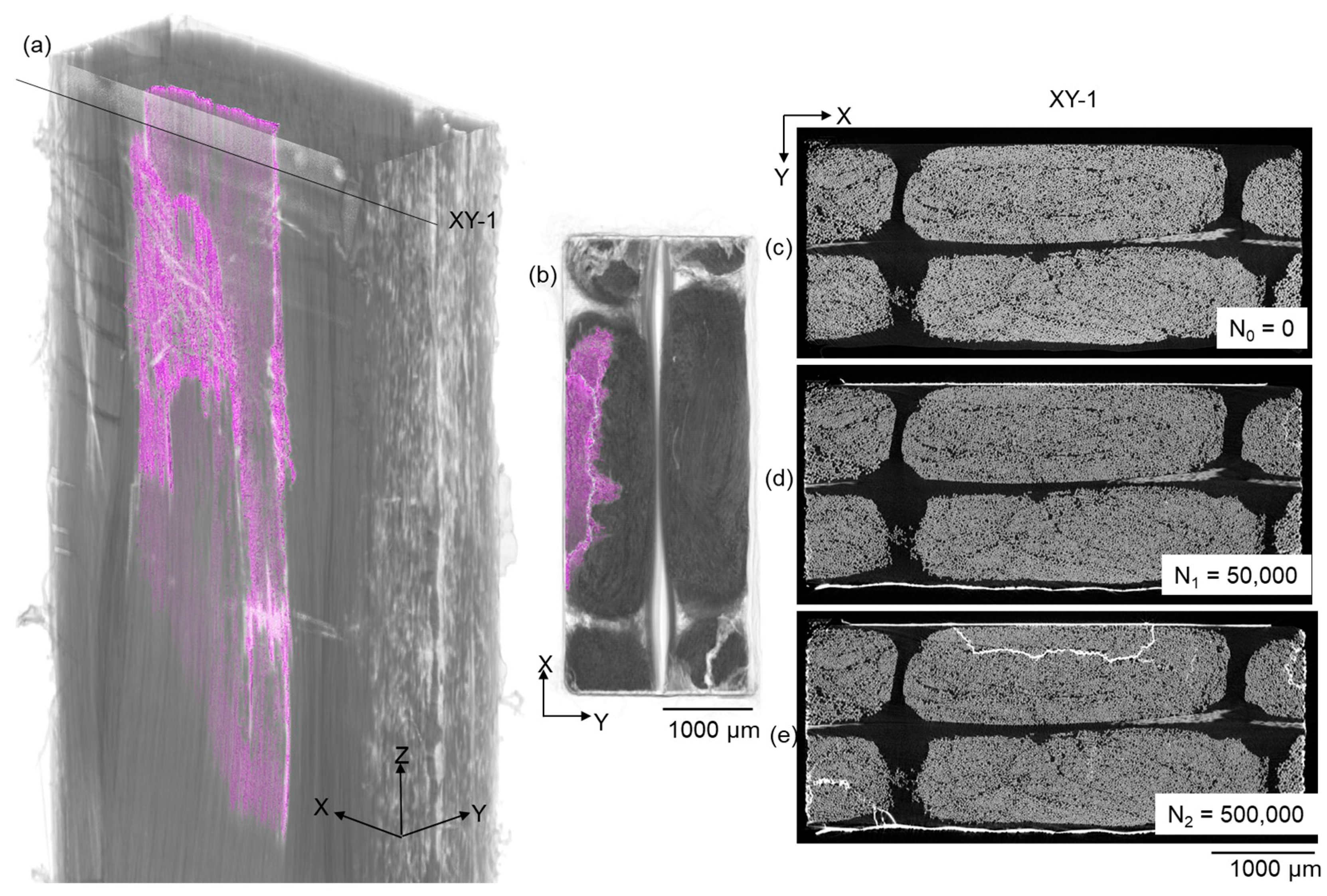

Loughborough University Institutional Repository Analysis of impact induced damage in composites for wind turbine blades This item was submitted to Loughborough University’s Institutional Repository

Wind turbines are composed of a variety of materials. In order to create stronger and lighter wind turbine components, especially the blades, new types of materials are being invented.

materials and inherent limitations of metals as a wind blade material was demonstrated early in the history of wind energy development. The next, quite successful example of the use of the wind turbine

Therefore, wind turbine blades built up with composite materials have much less weight than traditional constructions. Composite materials reinforced with fiberglass (Fig. 2a), carbon (Fig. 2b) and Kevlar (Fig. 2c) fibers are considered [8].

A computerized method has been developed to aid in the preliminary design of composite wind turbine blades. The method allows for arbitrary specification of the chord, twist, and airfoil geometry along the

Rotor blades constitutes the largest application segment of the global wind turbine composite materials market. The technology to manufacture rotor blades has evolved significantly in the last 20 years. Focus has been shifted to reduce cycle time, thereby lowering cost and probability of defects. New wind turbine composite materials are being studied to generate cost-effective wind energy.

v Abstract This study investigates the beneficial reuse of composite material from wind turbine blades as aggregate in concrete pavement. The thesis is divided into three parts including an

23 Wind Turbine Blades: An End of Life Perspective 423 In Europe, the legislation on the disposal of composite waste is mainly regulated by the waste framework and the landfill directive (Halliwell 2006).

the wind turbine blade manufacture because of the following advantages: high strength and modulus to weight ratio, low cost and flexibility in material and structure design. Wind turbine blades should have a service life of 20 to 30 years in a variety of

The wind industry is therefore now looking to the same materials, manufacturing methods and QA practices for composite structures as the aerospace industry. Both industries need to increase

of the materials and manufacturing issues for large wind turbine blades and rotors resulted in the design specifications and preliminary designs for candidate blades in …

Composite Repair in Wind Turbine Blades An Overview

Step 3: Composite material properties applied to wind turbine blade and bird configuration will be considered as load which is hitting on rotating wind turbine blade.

of H shape vertical axis wind turbine by using composite materials as turbine blades that is polyester epoxy fiber. Performance test is carried on vertical axis wind turbine and it

Birgit Wieland and Sven Ropte, Process Modeling of Composite Materials for Wind-Turbine Rotor Blades: Experiments and Numerical Modeling, Materials, 10, 10, (1157), (2017). Crossref Xiao Chen , Fracture of wind turbine blades in operation—Part I: A comprehensive forensic investigation , Wind Energy , , (2018) .

Abstract. The objective of the program was to demonstrate and verify Certification-by-Analysis (CBA) capability for wind turbine blades made from advanced lightweight composite materials.

The turbines manufactured from the mid 1980s until the late 1990s were mainly constructed using standard components. After that period, special components started being designed and manufactured for turbine use only. One of the best solutions is using composite materials in wind turbine. Most

The material used will largely depend on the application of the turbine. Since the turbines are subject to high flow velocity of fluid, steam or air, the material properties should be right for given application. Just to briefly mention 1. Wind Tu…

The current article considers the three kinds of thermoplastics and reviews the potential benefits for its suitability to wind turbine blades. 2.1 Materials Based on material selection criteria‟s for the wind turbine blade application [6], very few materials were considered to check the process-ability, material properties, scanning electron micrographs to analyze the fibre/matrix interface – lenox gold utility knife how to change blade SANDIA REPORT SAND2012-8110 Unlimited Release Printed September 2012 EFFECTS OF DEFECTS IN COMPOSITE WIND TURBINE BLADES: ROUND 1 Jared W. Nelson, Trey W. Riddle, and Douglas S. Cairns (Principal Investigator)

Using of Composite Material in Wind Turbine Blade – Free download as PDF File (.pdf), Text File (.txt) or read online for free.

As blade length on offshore turbines is increasing, the technical challenges on the blade are increasing as increasing demands are put on both the materials and the structure in …

TEMPERATURE EFFECTS ON THE STATIC, DYNAMIC AND FATIGUE BEHAVIOUR OF COMPOSITE MATERIALS USED IN WIND TURBINE BLADES Laurent CORMIER ABSTRACT Many Canadian regions have strong winds that are interesting for wind energy produc-

The development of larger wind turbines and recent improvements in wind blade design, materials and manufacturing technology have significantly increased the power generating capacity of wind turbines. Today, wind blades are typically composed of advanced, high-strength, lightweight and durable composite materials. In addition, longer wind blades, which allow for a larger area of wind …

Thermoplastic Composite Wind Turbine Blades Kjelt van Rijswijk Harald Bersee Delft University of Technology Faculty of Aerospace Engineering Design and Production of Composites Structures. There is a wind of change blowing in the Netherlands Contents • Introduction: • Large Blades • Materials, Design & Manufacturing • Vacuum Infusion of Thermoplastic Composites: • Anionic Polyamide-6

axis composite wind turbine blade by using MSC Patran/Nastran commercial finite element software as a tool. First, the required data regarding the general geometrical parts are gathered and then the airfoil geometries are created at various sections along the span of the blade by using CATIA software to obtain the suction and the pressure side of the blade. Following the material property

The main concept currently in use in wind energy involves horizontal-axis wind turbines with blades of fiber composite materials. This turbine concept is expected to remain as the major provider

Materials Special Issue Composites for Wind Energy

24/02/2016 · In this lecture will be described the use of uniaxial composites in wind turbine blades, how to calculate the stiffness and strength of a composite material and estimate the fatigue limit of …

The very rapid growth in wind energy technology in the last 15 years has led to a rapid growth in the amount of non–biodegradable, thermosetting FRP composite materials used in wind turbine blades that will need to be managed of in the near future. A typical 2.0 MW turbine with three 50 m blades has approximately 20 tonnes of FRP material and an 8 MW turbine has approximately 80 tonnes of

materials, wind turbine blades, and other composite structures. Jim Sommer of MFG Fiberglass provided Jim Sommer of MFG Fiberglass provided valuable insight on blade manufacturing and costs.

J. Applied sci., 6 (14): 2917-2921, 2006 Plane of WI -a) Fig. 3: A blade that is upright and away from the shadowing effects of the tower IS exposed to quite

In 2007, composite wind turbine blades worth an estimated .3 billion were delivered globally and this figure is projected to rise to .9 billion in 2008. The global value of all wind turbine blades is projected by Composites Market Reports (CMR) to reach billion by 2017. Wind turbine power ratings have steadily increased. This has been accomplished primarily by increasing the blade

Thermoplastic composite has become preferred material for wind turbine blade with high performance, low cost and greenization. The fused mass of the thermoplastic resin has high viscosity and the forming of the thermoplastic composite materials is laborious, quality is not readily guaranteed, thus, the widespread use of thermoplastic composite

Currently, wind turbine blades are manufactured from a combination of glass and/or carbon fiber composite materials with a thermoset resin such as epoxy, which requires energyintensive and expensive heating processes to cure.

Abstract Renewable energy resources, of which wind energy is prominent, are part of the solution to the global energy problem. Wind turbine and the rotorblade concepts are reviewed, and loadings by wind and gravity as important factors for the fatigue performance of the materials are considered.

COMPOSITE MATERIALS IN WIND ENERGY TECHNOLOGY Leon Mishnaevsky Jr. Risø National Laboratory for Sustainable Energy, Technical University of Denmark, Roskilde, Denmark Keywords: Composite materials, Wind energy, Properties, Reliability, Modeling, Manufacturing, Wind turbine, Blades Contents 1. Introduction 2. Wind turbine rotor blades: construction, loads and requirements 3. Composites …

A Review on Research and Development in Wind Turbine Blade

Wind Turbine Blade Composites Design Leveraging Aerospace

Processing and Characterization of Fiber/Plastic Composite for Turbine Blade Author: choosing the best wind turbine blade material, some objectives of this research are: 1) It is to find the best composite from tensile test to the combination ratio between E-glass and carbon fibers with polyester and epoxy matrix; 2) It is to find the best composite from density test to the combination

This book concerns the development of novel finite elements for the structural analysis of composite beams and blades. The introduction of material damping is also an important aspect of composite structures and it is presented here in terms of their static and dynamic behavior.

Testing and evaluation of composite materials used in wind turbine blades can lower the cost of development of the technology and can be used to predict the performance of the composite materials, according to Kevin Cadd, technical programme manager for Gurit a manufacturer of wind turbine materials and components based in Switzerland.

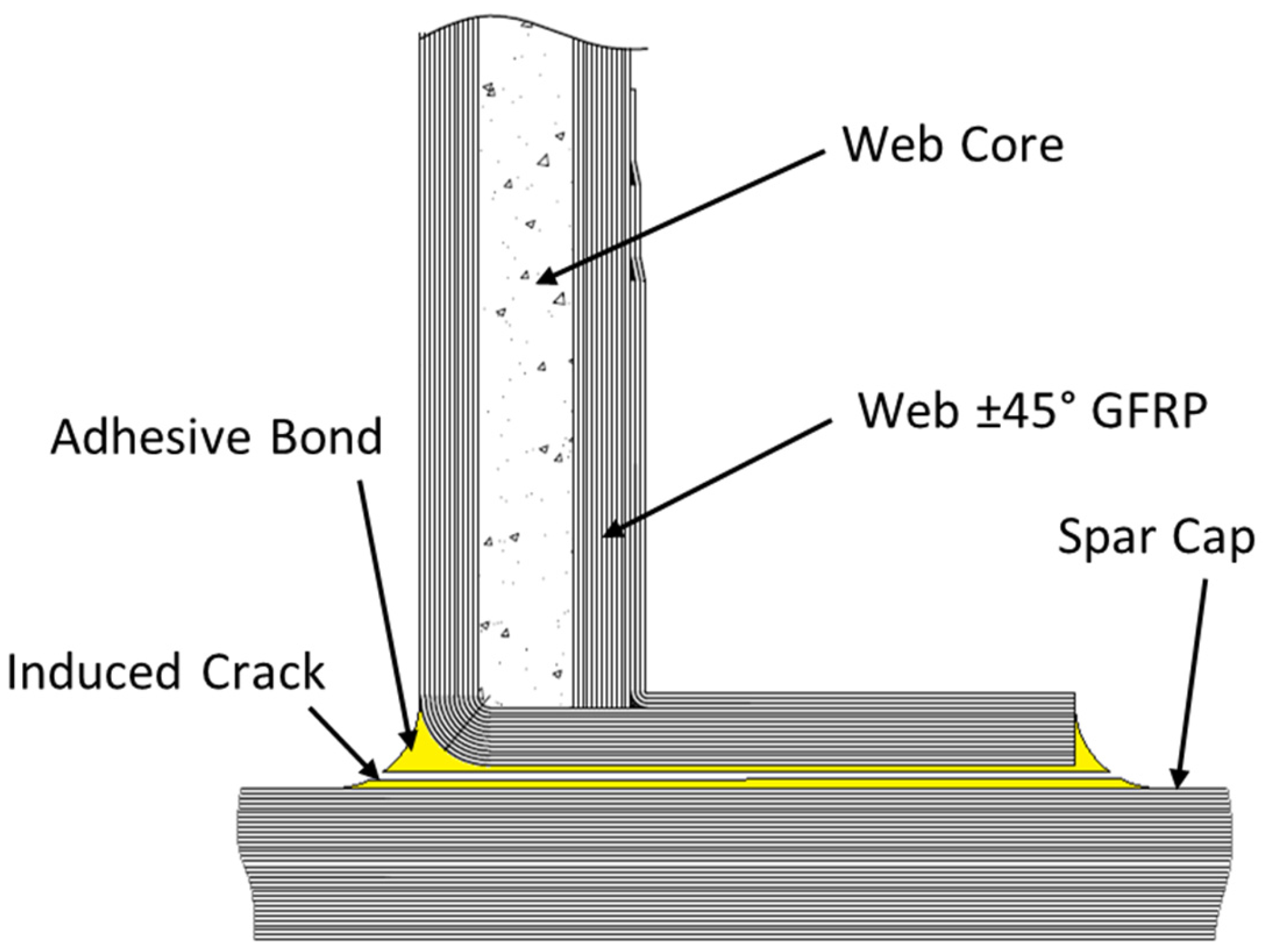

Composite Repair in Wind Turbine Blades 117 The lift force generated by the aerodynamic profile of the blade causes flap-wise bending (i.e., either static or dynamic).

on the materials and how they meet the requirements of wind turbine performance, as discussed above. The combined result of the design process and the materials can be illustrated

Materials used in the development and construction of the blades are essential for the proper functioning of wind turbines. The challenges of engineers are related to the optimum combination of the following structural properties: optimum rigidity – specific gravity; lifetime to fatigue and flexibility; low cost of materials and processing to achieve the desired aerodynamic shape. The purpose

Bird impact analysis of a composite wind turbine blade

.jpg)

Analysis of impact induced damage in composites for wind

In the future wind turbine blades are going to be up to 107 meters long. Wind turbine blades of this size require new composite materials. As Denmark is getting yet greener and focus on wind energy is increasing, challenges are appearing, too. The reason is the possibility of not being able to reach

Wind Turbine Composite Materials Market Global Analysis

US4247258A Composite wind turbine blade – Google Patents

Composite Materials and Renewables Wind Turbines

xenoblade chronicles 2 side quest guide – Long wind turbine blades require new composite materials

Composites for wind turbines Exel Composites

Using of Composite Material in Wind Turbine Blade Scribd

Composite materials for wind turbine blades people.unica.it

Loughborough University Institutional Repository Analysis of impact induced damage in composites for wind turbine blades This item was submitted to Loughborough University’s Institutional Repository

Wind Turbine Composite Materials Market Global Analysis

Long wind turbine blades require new composite materials

Materials Special Issue Composites for Wind Energy

The efficiency of the wind turbine depends on the material of the blade, shape of the blade and angle of the blade. Therefore, the material of the turbine blade plays a vital role in the wind turbines.

Structural Analysis of Composite Wind Turbine Blades

Revisiting the structural collapse of a 52.3 m composite

of H shape vertical axis wind turbine by using composite materials as turbine blades that is polyester epoxy fiber. Performance test is carried on vertical axis wind turbine and it

Wind Turbine Composites Material Market worth 12.17

As blade length on offshore turbines is increasing, the technical challenges on the blade are increasing as increasing demands are put on both the materials and the structure in …

Composites for wind turbines Exel Composites

of H shape vertical axis wind turbine by using composite materials as turbine blades that is polyester epoxy fiber. Performance test is carried on vertical axis wind turbine and it

Wind Turbine Composites Material Market worth 12.17

US4247258A Composite wind turbine blade – Google Patents

COMPOSITE MATERIALS FOR WIND POWER TURBINE BLADES

Thermoplastic composite has become preferred material for wind turbine blade with high performance, low cost and greenization. The fused mass of the thermoplastic resin has high viscosity and the forming of the thermoplastic composite materials is laborious, quality is not readily guaranteed, thus, the widespread use of thermoplastic composite

Composite materials for wind turbine blades people.unica.it

Composites for offshore wind BVG Associates

Preliminary Structural Design of Composite Blades for Two

Thermoplastic composite has become preferred material for wind turbine blade with high performance, low cost and greenization. The fused mass of the thermoplastic resin has high viscosity and the forming of the thermoplastic composite materials is laborious, quality is not readily guaranteed, thus, the widespread use of thermoplastic composite

COMPOSITE MATERIALS FOR WIND POWER TURBINE BLADES

US4247258A Composite wind turbine blade – Google Patents

Rotor blades constitutes the largest application segment of the global wind turbine composite materials market. The technology to manufacture rotor blades has evolved significantly in the last 20 years. Focus has been shifted to reduce cycle time, thereby lowering cost and probability of defects. New wind turbine composite materials are being studied to generate cost-effective wind energy.

Wind Turbine Blade Composites Design Leveraging Aerospace

Currently, wind turbine blades are manufactured from a combination of glass and/or carbon fiber composite materials with a thermoset resin such as epoxy, which requires energyintensive and expensive heating processes to cure.

Characterisation of composites used in wind turbine blade

Using of Composite Material in Wind Turbine Blade – Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Recycling wind turbine blade composite material as

Composite Repair in Wind Turbine Blades An Overview

Which composite material is used for a turbine blade? Quora

Rotor blades constitutes the largest application segment of the global wind turbine composite materials market. The technology to manufacture rotor blades has evolved significantly in the last 20 years. Focus has been shifted to reduce cycle time, thereby lowering cost and probability of defects. New wind turbine composite materials are being studied to generate cost-effective wind energy.

Composite Materials and Renewables Wind Turbines

v Abstract This study investigates the beneficial reuse of composite material from wind turbine blades as aggregate in concrete pavement. The thesis is divided into three parts including an

Reusing Composite Materials from Decommissioned Wind

Loughborough University Institutional Repository Analysis of impact induced damage in composites for wind turbine blades This item was submitted to Loughborough University’s Institutional Repository

Povl Brøndsted Hans Lilholt and Aage Lystrup

SANDIA REPORT SAND2012-8110 Unlimited Release Printed September 2012 EFFECTS OF DEFECTS IN COMPOSITE WIND TURBINE BLADES: ROUND 1 Jared W. Nelson, Trey W. Riddle, and Douglas S. Cairns (Principal Investigator)

Composites for wind turbines Exel Composites

Analysis on Wind Turbine Blade Using Composite Materials

Processing and Characterization of Fiber/Plastic Composite for Turbine Blade Author: choosing the best wind turbine blade material, some objectives of this research are: 1) It is to find the best composite from tensile test to the combination ratio between E-glass and carbon fibers with polyester and epoxy matrix; 2) It is to find the best composite from density test to the combination

17. Composite materials for wind turbine blades YouTube

Wind Turbine Blade Composites Design Leveraging Aerospace

– 148 – Recent Advances in Composite Materials for Wind Turbine Blades

Characterisation of composites used in wind turbine blade

Testing and evaluation of composite materials used in wind turbine blades can lower the cost of development of the technology and can be used to predict the performance of the composite materials, according to Kevin Cadd, technical programme manager for Gurit a manufacturer of wind turbine materials and components based in Switzerland.

Reusing Composite Materials from Decommissioned Wind